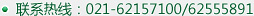

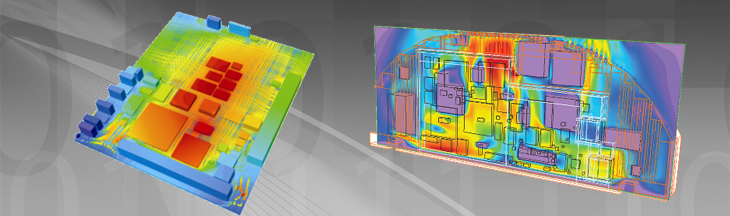

Von Mises stress through C4/CBGA package displayed in Flomerics's Flotherm thermal management pac |

March 2000 |

|

The European Commission has accepted a proposal for a three-year collaborative research project, code named PROFIT, to improve thermal design of electronics. PROFIT aims to create methods and tools to enable rapid assessment of thermal parameters affecting yield, performance, reliability and safety in electronic equipment. It is widely accepted that mechanical stresses due to temperature gradients and temperature cycling cause the majority of failures in today's electronic systems. However, analysis is seriously hampered by the lack of standard methods to predict temperature gradients in time and space, with sufficient accuracy. The PROFIT project aims to overcome these drawbacks through major improvements in experimental techniques to acquire better input data for thermal modelling via non-linear parameter estimation methods, and improved transient thermal characterisation of components. Standardisation is considered an important deliverable. Ultimately, the results of PROFIT will be suited for implementation in emerging virtual prototyping methods and physics-based reliability analysis software. The industrial challenges and solutions offered by PROFIT are:

The PROFIT project is co-ordinated by Philips Research. The project consortium includes semiconductor manufacturers (Philips Semiconductors, Infineon Technologies, ST Microelectronics); system makers (Nokia, Philips); thermal analysis software vendors (Flomerics, MicRed); a statistics expert centre (Centre for Quantitative Methods); a university specializing in electrothermal analysis and transient measurements (Technical University of Budapest); and a major research institution contributing in the fabrication of test dies and tool integration (TIMA). The work programme will focus on major improvements in thermal analysis throughout the design chain, from device via package and board to system. Novel test set-ups will be built in order to measure important parameters required for accurate numerical analysis, such as interface resistances, emissivities, local boundary conditions and local board thermal conductivities. Transient measurements at device and package level will be performed to assess data quality. Analysis of the data will be treated with novel, non-linear parameter estimation methods. Software will be improved, developed and integrated to facilitate the application of the project results in performance and reliability calculations. Various demonstrators showing the final deliverables are foreseen. The steady-state thermal characterisation of compact models will be extended to the transient domain. Yearly workshops will be organised to promote discussion amongst experts, and to facilitate early standardisation. In short, the innovative elements of the project are:

|

沪公网安备 31010602003953号

沪公网安备 31010602003953号